Coastal ocean frontages are some of the few places on earth that experience the full wrath of nature. These places experience strong waves and the violence of fluctuating tides which lead to massive erosion and land deterioration.

These harsh weather conditions make coastal projects some of the most challenging to work on. Given the right construction techniques and elements, these areas can house some of the world’s most elegant architectural pieces.

It takes the application of the right restorative construction solutions that will enable the coastal property to withstand harsh weather conditions. One of the main ways to do this is through advanced coastal retaining wall systems.

The Poplar Saga

Poplar Island which is located along the eastern seaboard in Maryland’s once-elegant Chesapeake Bay fell victim to rapid erosion and deterioration in the early 1900s in the wake of fluctuating tides. In no time, the extensive island of over 2,000 acres was down to just about 4 acres with scarce fauna.

It was so evident that Poplar Island was slowly approaching its sunset days since the landmass was rapidly washing away and its natural wildlife, which was a renowned tourist attraction, was being wiped out.

Today, Poplar Island is a ‘living’ testimony of what restorative engineering solutions can do. The island was given a second chance to thrive, thanks to the creative engineering solutions offered by McLean Contracting Co., York Building Products, and MagnumStone retaining wall solutions.

The Restoration of Poplar Island

Dredging Materials

To save the face of Poplar Island, the U.S. Army Corps of Engineering (USACE), the Maryland Port Administration, and the Maryland Department of Transportation took on a project to restore the island using dredging materials from the shipping channels of the Port of Baltimore and the Chesapeake Bay.

This project saw the construction of marshes and wetlands which are now a habitat for shorebirds, waterfowl, ivy plants and aquatic plants.

The Big Block Gravity Wall System

In a project dubbed the Spillway 17 and Spillway 19 which was awarded to McLean Contracting Company, USACE picked a big block gravity wall system for the restoration of the island. These retaining wall systems were to be used in a sensitive part of Poplar Island on which overhead access roads and large culverts were to be constructed.

The idea was to erect four big block gravity walls (one on either side of each culvert) to support the roadways above the two culverts.

This project, which brought together Earth Retention Systems, a wall engineering company, and York Building Products, MagnumStone wall manufacturers, suffered a major blow at the engineering phase due to fluctuating tides and the presence of soft soils which weren’t able to effectively hold the weight of the heavy solid walls.

The Collaborative MagnumStone Wall Design

When the big block gravity retaining wall system failed, the McLean-led team had to overcome its shortcomings and deliver the project successfully to USACE’s satisfaction. MagnumStone’s hollow-core block system came in handy.

Tall walls are a common sight in coastal retaining wall projects. MagnumStone retaining wall systems provide the engineering design flexibility that facilitates the construction of tall walls with significantly less weight due to the 40% less concrete used to make the blocks.

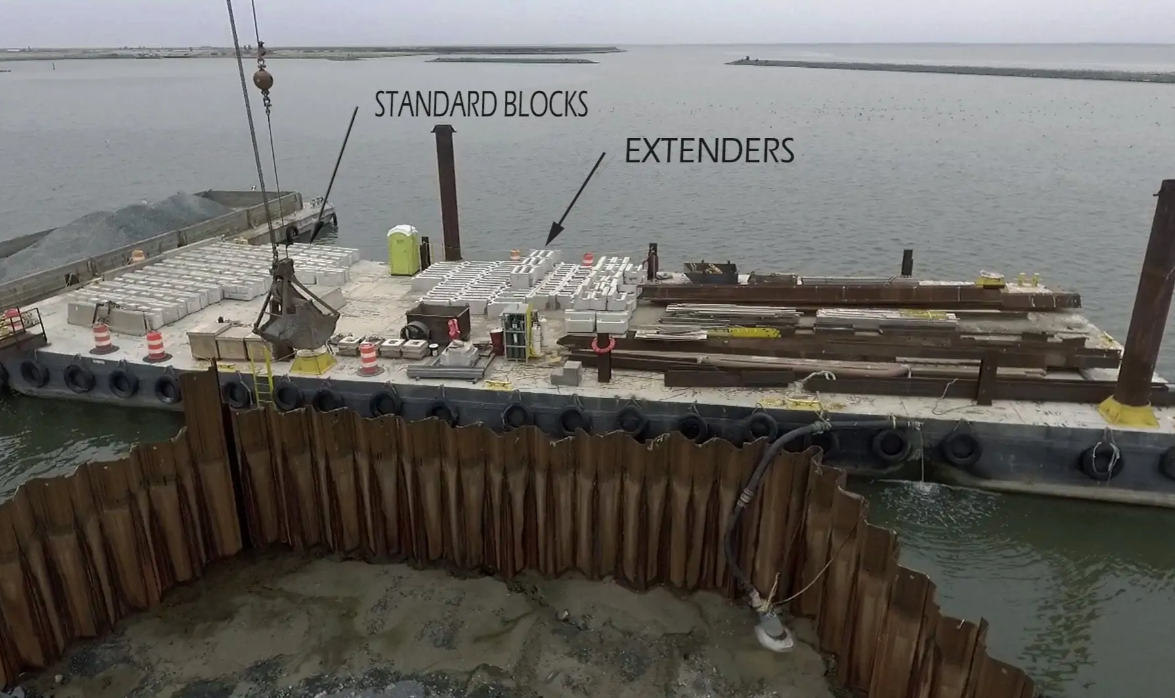

The tall retaining walls separate the coastal ocean frontage from buildings and provide an allowance for other amenities such as parking lots. The MagnumStone extender system allows you to attain the height you desire with a relatively smaller depth. It slides into the back-side of the retaining wall, allowing for a small excavation while making for a tall wall.

Environmental Conservation

Coastal areas are homes to a plethora of plant and animal life, forming a rich ecosystem. These areas should be protected. After the successful restoration of Poplar Island, the island boasts of hosting several species of migratory shorebirds and waterfowl, a host of fish and turtles and so many insect species. It has over 1,000 acres of wildlife coverage.

MagnumStone retaining wall system promotes environmental sustainability. The hollow core design uses 40% less concrete compared to the traditional solid block retaining wall.

Due to the lesser amount of concrete used to make these blocks, the carbon footprint of MagnumStone retaining walls is significantly reduced. Additionally, the resultant lightweight retaining wall blocks mean that lesser trips are made to the site during construction, hence reducing the number of greenhouse gases produced during transportation to the site.

Less equipment, energy, and labor are required to install the hollow core retaining wall blocks leading to large cost savings and efficient installation. This also reduces the environmental impact of the project. As well, the extender system is used to compensate for the reduced weight instead of additional concrete.

Conclusion

Poplar Island experiences very harsh weather, making it vulnerable to soil erosion and degradation. The severity of the extreme weather makes coastal retaining wall projects complex to actualize.

MagnumStone retaining walls offer the best solution to help with the preservation of the waterway. It allows for engineers to construct tall walls with less excavation since they are lightweight and are served with the innovative MagnumStone extender system which slides into the back-side of the retaining wall, allowing for a tall wall with sufficient support.

Using 40% less concrete, MagnumStone’s system is an eco-friendly alternative to traditional retaining wall blocks and you also add palm trees to the whole setting. Preservation of the waterways must also incorporate environmental conservation because of the native plants and animals that call coastal areas home.