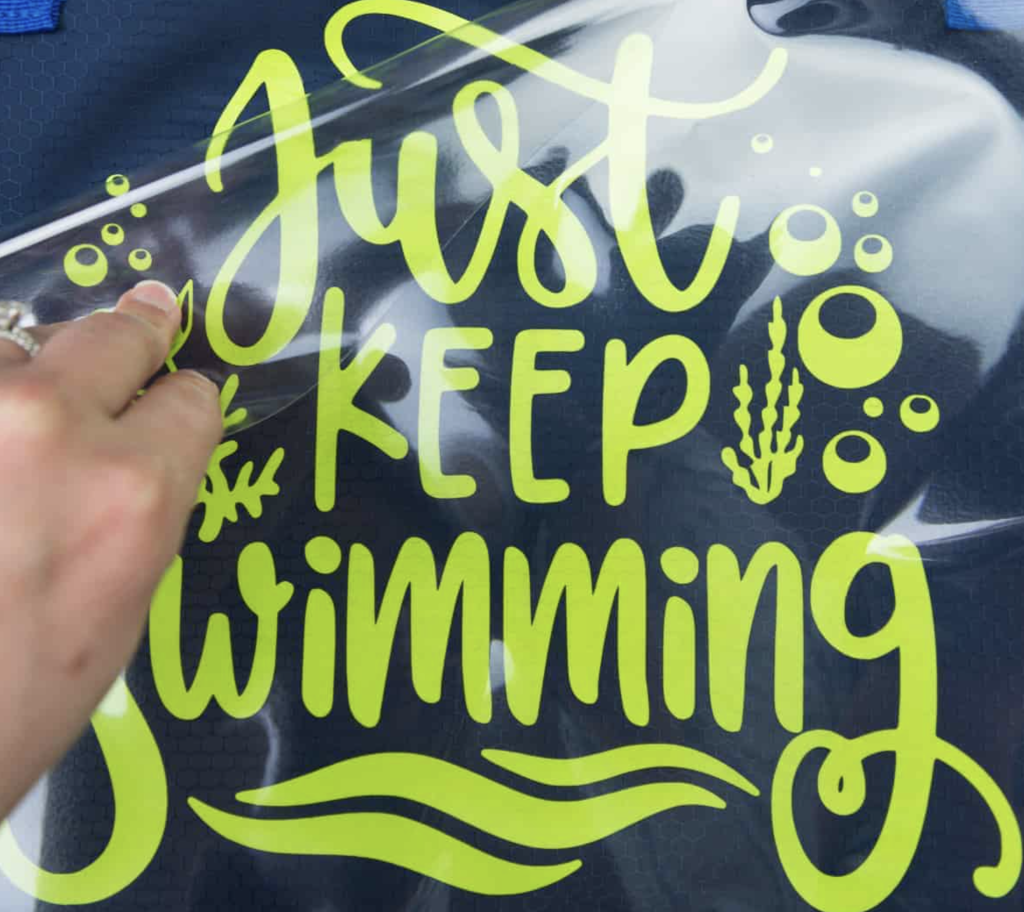

Heat transfer vinyl, which is popularly known as HTV, has revolutionized the world of customization, allowing individuals and businesses to create personalized and unique designs on various fabric surfaces.

From clothing to accessories and home decor items, HTV has made it easier than ever to bring creative wishes and make their designs or choose their preferred designs to life.

However, when it comes to non-woven polyester bags, many people wonder if HTV is a suitable option for customization or not; often, the question comes to mind.

In this blog, we will discuss the details of using HTV on nonwoven polyester bags, discussing the challenges, tips, and best practices for achieving the desired results of your preferred designs.

What are Non-Woven Polyester Bags?

Non-woven polyester bags, a testament to the eco-friendly and versatile nature of using HTV on different fabric types, have surged in popularity. Crafted from durable bonded polypropylene fibers, these bags represent a sustainable alternative to traditional plastic bags, appealing to eco-conscious individuals and businesses alike.

Challenges of Applying HTV to Non-Woven Polyester Bags

Non-woven polyester bags offer several advantages, but they also present unique challenges when it comes to applying HTV.

Here are some of the key challenges to consider

- Texture and Porosity– Non-woven polyester bags have a textured surface and are more porous than traditional fabric materials like cotton or polyester. This can affect the adhesive of the, making it less straightforward to achieve a strong bond.

- Temperature Sensitivity– The temperature required for heat transfer may vary depending on the type of non-woven polyester used. Some non-woven polyester is heat sensitive, and applying it at high temperatures may damage the material. Referencing a heat settings guide is the most effective way to determine what temperature to utilize.

Tips for Applying HTV to Non-Woven Polyester Bags

Nonwoven polyester is a suitable material for heat transfer vinyl because it can withstand the heat required for the application process without melting or getting damaged. These bags are eco-friendly and tough, and with the right care, you can personalize them for your personal use or any other use.

1. Conduct a Test Run

Before applying HTV and start customizing your non-woven polyester bag with HTV, it is a good idea to do a trial run. For that, you must pick a small or hidden area of the bag and then apply the HTV there first. Testing on a small area avoids potential disappointment and loss and helps you fine-tune your customization process. This will help you check how well the heat transfer vinyl sticks to the material and how long it lasts. It is like trying on a new pair of shoes to make sure they fit properly to your feet before taking a long walk.

2. Follow the Manufacturer’s Instructions

HTV products vary in both types and brands. Each has its specific recommendations for temperature, pressure, and application time. It is recommended to always carefully read and adhere to the instructions provided with your HTV. This step is like following a recipe when you are cooking a delicious meal. The precise execution of each step and instruction leads to the best outcome, ensuring your HTV adheres correctly and looks good.

3. Pre-Heat the Bag

Before applying the HTV, pre-heat the non-woven polyester bag for a few seconds. This step is one of the most important as it helps to eliminate any moisture and wrinkles on the bag’s surface. This makes the canvas surface clean and smooth for your vinyl designs. Things work efficiently when they are preheated in the case of polyester bags to ensure a successful HTV application.

4. Choose the Right HTV Type

Not all HTVs are created equal. Each has its characteristics and features. Also, some are specially formulated for challenging materials like non-woven polyester.

Before buying any HTV, check whether the HTV is designed for specific fabrics or those with strong adhesive properties. Using the right HTV for the specific fabrics makes the customization process smoother and more effective.

5. Use a Pressing Pillow or Teflon Sheet

When applying HTV inside the bag, include a pressing pillow or Teflon sheet. This additional layer helps to create a flat and even surface on your fabric or within the bag.

This prevents heat from transferring through to the opposite side and safeguarding the bag’s integrity. It keeps the work area from being damaged and keeps the work area in a smooth condition.

6. Apply Firm and Even Pressure

When pressuring the heat transfer vehicle onto the bag, ensure that you apply consistent and firm pressure to the fabric. This step is paramount for secure HTV adhesion. With even pressure, all the ingredients stay together cohesively.

7. Allow Cooling Time

After applying the HTV, you must allow it to cool completely before removing the transfer sheet. This cooling period fosters a strong bond and preserves the design’s integrity. It is advised that you wait patiently for your final result. This will enhance the final result’s quality and appearance.

Conclusion

While it might seem tricky initially, you can make cool designs on non-woven polyester bags using HTV if you follow some easy and simple steps. To succeed, remember to do the test runs, read and stick to the HTV guidelines and instructions, and use the right tools and techniques.

By doing this, you can dive into the world of HTV customization on non-woven polyester bags with confidence. Let your creativity shine, and you will turn these sustainable bags into awesome, unique accessories or promotional items people will love and adore.

In short, even though non-woven polyester bags can be a bit challenging for HTV, you can conquer it with the right approach.